Blog

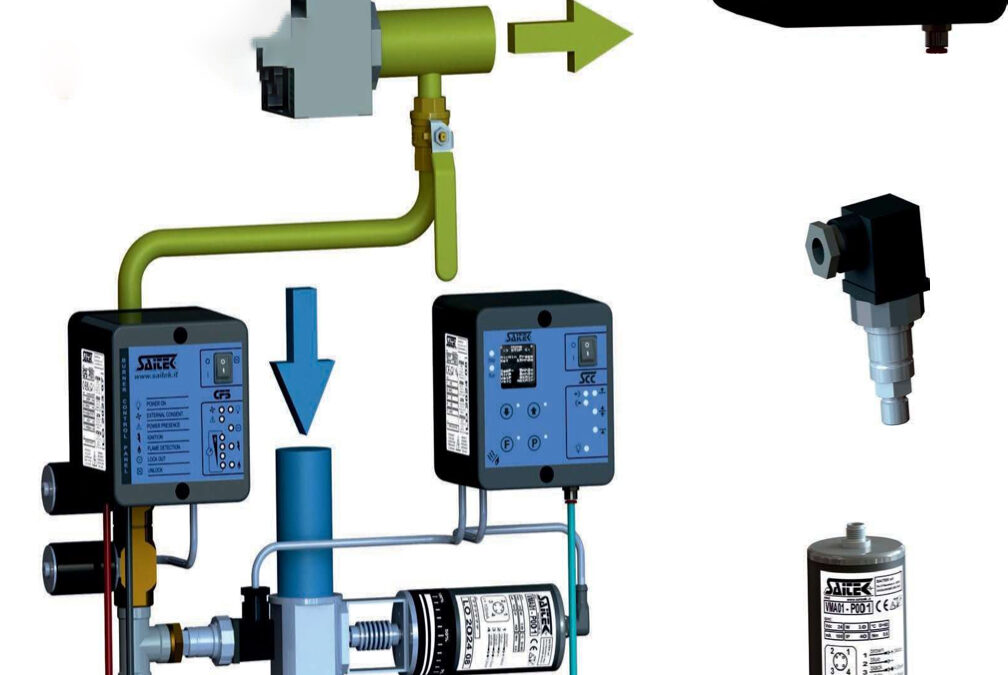

Combustion Control System (CCS) for ceramic kiln (1)

Delivery 1 of the Combustion Control System for the ceramic kiln. From fixed air to modulated air How the simultaneous regulation of air and gas improves the efficiency and stability of the firing process. In the Combustion Control System for the ceramic kiln, firing...

The Combustion Control System (CCS) is already generating interest among major ceramic manufacturers.

After the presentation of the SCC (Combustion Control System) by Grins Energy Efficiency, the first evaluations carried out with referents of the ceramic sector have confirmed what we already anticipated a few months ago:- Simultaneous real-time optimization of air...

Refractory engobe for ceramic rollers operating at high temperatures

In ceramic firing processes, the rollers are faced with increasingly demanding thermal cycles, corrosive environments and undesired material accumulations that affect the final quality of the product. The durability and stability of the conveying system inside the...

Training in minor operations in facilities with Legionella risk.

Royal Decree 487/2022, of June 21, establishes the obligation for the personnel of facilities with Legionella risk to have training in minor Legionella operations. This training must enable them to carry out minor maintenance and control operations in safe conditions...

Chemical solutions for the ceramic industry

At Todaquimia - Grins Ceramic Solutions, we provide a variety of chemical solutions for the ceramic sector, and our commitment to innovation and continuous improvement allows us to offer advanced chemical solutions for the ceramic industry. Through our R+D+i...

Refractory materials for ceramic furnaces

Grins Ceramic Solutions has an extensive track record in industrial solutions for ceramics, offering 360º interventions directly in the plant, and enhancing a wide range of refractory materials for ceramic kilns.In addition, we provide a specialized assistance and...

Total combustion control, efficiency in ceramic furnaces

Launch of SCC (Combustion Control System) by Grins Energy Effiency. Take the next step in the control of your ceramic kilns At Grins Energy Efficiency we understand that combustion is the vital core of every ceramic kiln, so combustion control is essential to its...

Ceramic glaze water treatment, technical complexity and specialized solutions (Part V)

Ceramic glaze wastewater represents a challenge in industrial treatment. Its complexity goes beyond conventional water, micronized frits, heavy metals (Zn, Pb, B) and specialized additives that require advanced engineering solutions. Unlike water generated in...

Industrial scrubbers for ceramic atomizer plants (Part IV)

In a ceramic atomization plant, water treatment is not an auxiliary process, but a strategic variable for production stability. For this reason, the use of industrial water treatment plants is essential. Atomizers represent the operational core of ceramic plants,...

Which ceramic roller do you need for your oven?

Inside a ceramic kiln, not all rollers work in the same way. Thermal, chemical and mechanical conditions vary from zone to zone, and this makes it necessary to select the right roller according to its technical behavior.