Pyroxal 50 and Pyroxal HT grades

ICRA’s ceramic rollers, in their different grades such as PYROXAL 50 and PYROXAL HT, are specially designed to operate in the most demanding areas of ceramic kilns. Ceramic rollers are designed to withstand heavy loads, high temperatures, chemical attack and to effectively resist thermal shock.

Thanks to these demanding product characteristics, the ceramic rollers considerably minimize maintenance interventions, continuous stops and starts in the kilns, thus reducing the energy losses caused in these non-productive moments, as well as providing greater safety of planarity in the transport of the ceramic pieces along the different areas of the kilns.

Both PYROXAL 50 and PYROXAL “HT” rollers are rollers with a high resolution in the problems of impurity adhesions, due to the fact that they are manufactured with a minimized number and size of pores. It should be noted that at high temperatures the ceramic rollers maintain a high mechanical resistance, thus excluding a greater breakage of the same, and therefore an important reduction of inorganic residues.

ICRA PYROXAL “HT” rolls are the most resistant to expansion differences and therefore to surface tension at high temperatures. They are suitable for tension with deformation.

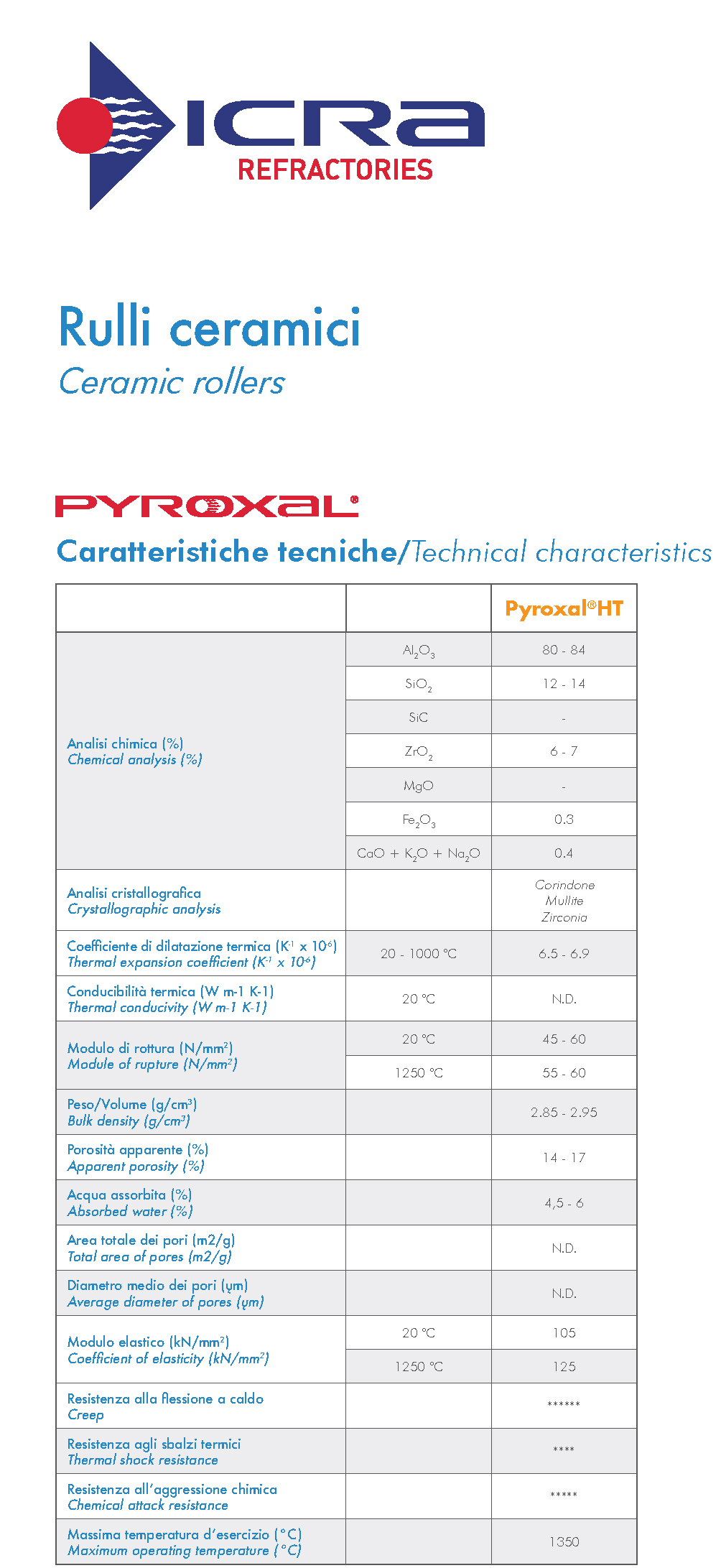

Deformations are smaller for the ceramic roll with higher modulus of elasticity, in this case the material is said to be more rigid and remains more unalterable. (See data sheet in image).

The main factors that cause the degradation of ceramic rolls are the development of a glassy phase and the presence of open porosity. These aspects are critical as they act as pathways for contaminants to infiltrate the ceramic rolls, accelerating their deterioration.

To address this problem, ICRA has carefully adjusted the chemical composition of the ceramic rolls, minimizing elements such as Fe2O3 and TiO2, as well as fluxes such as Na2O, K2O and CaO.

This care contributes to a lower accumulation of dirt on the ceramic rollers and increases their capacity to resist chemical aggressions, which in turn reduces their level of contamination.