How technical control of water treatment reduces your operating costs and makes us more competitive.

A poorly adjusted treatment system or with inappropriate reagents not only means higher consumption of reagents or sludge generation, it directly impacts operating costs, process stability and the time your team spends intervening in a facility that should be stable. At Grins Environmental Engineering we believe that being competitive is not about offering low prices on equipment, but about ensuring that your WWTPI operates with the lowest possible operating costs. And we achieve this with technical knowledge, optimized chemical design and real plant support. Reagents that are not pH-dependent and that eliminate the addition of other reagents to adjust pH, the elimination of additives that increase the conductivity of the treated water or the use of ultra-concentrated products, help us to reduce operating costs significantly while providing stability to the circuits and avoiding adjustment interventions in the treatment plant.

Turbidity as a profitability indicator

In industrial wastewater treatment plants in the ceramics sector, turbidity of treated water is not an aesthetic data, it is one of the most representative indicators of the efficiency of the physicochemical process. When turbidity is high, structural problems in the system are hidden:

- Incorrect dosage of coagulants or flocculants.

- Deficient decanting due to poor sizing or unstable hydraulic load.

- Increased solid carryover affecting the filter press and downstream processes.

- Unnecessary sludge generation and more frequent cleaning.

- Need for constant interventions by the maintenance team.

Each mismanaged NTU (turbidity unit) means more chemical, more sludge, more cost and more time wasted.

Why is Grins Industrial Solutions more competitive?

Our difference is not only in the design of the installation, but in its day-to-day operational performance.

As a specialized chemical engineering company, we start from a process approach that allows us to:

- Perform preliminary Jar-Tests to select exact reagents and minimum dosages.

- Design systems that maintain turbidity at optimal levels (≤10 NTU), even with variable discharges.

- Automate the reading of key parameters to act before the problem appears.

- Plan a technical maintenance system that allows working with stability, without weekly adjustments.

- Accompany the maintenance manager with a periodic follow-up system that avoids progressive deviations.

The result is a WWTPI that works on its own, with less intervention, less consumption and lower costs.

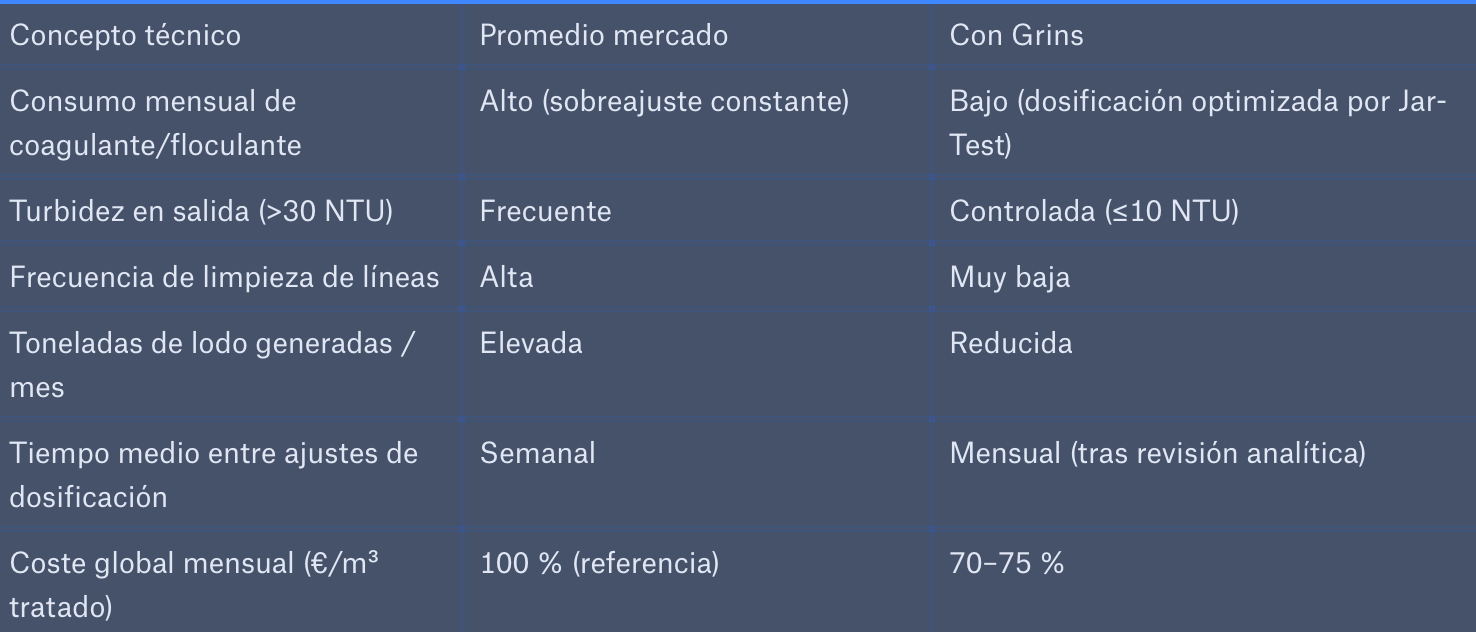

Technical comparison of market operation vs. Grins

Performance-oriented technical monitoring

Our work model is not only limited to installing equipment, we integrate with your technical team to ensure that the WWTPI works as it should.

Our periodic operational control tasks include the following:

- Verification of the general operation of the WWTPI.

- Maintenance of the filter press and auxiliary equipment.

- Control, calibration and cleaning of turbidity, pH and conductivity probes.

- Checking the condition of metering pumps and detecting leaks.

- Jar-Test trials to readjust dosages if discharge conditions change.

- Controlled reagent replenishment and stock tracking.

- Flow control and monthly sampling for performance evaluation.

Monthly water analysis to maintain efficiency

We perform monthly analytical controls that allow us to detect small deviations before they become operational problems. The results are analyzed together with the maintenance managers and allow decisions to be made with real data.

Parameters analyzed:

- Total hardness

- Conductivity

- Salinity

- pH

- Suspended matter

- Total dissolved solids

- COD

- Boron

- Zinc

- Aluminum

- Iron

Jar-Tests are repeated whenever necessary, especially when raw material batches change or alterations in production cycles are detected.

Controlled turbidity, more efficient process and lower costs

For us, turbidity is not just a data, it is a key indicator of the operating cost of your WWTP.

And that makes us more competitive, because we design, adjust and maintain facilities that work with stability, without cost overruns and without the need to over-intervene.

If you manage a ceramic plant and are faced with high consumption, excessive sludge production or high turbidity water, we are here to help you.